1 Features

● full-featured, high intelligence, set of operating parameters and operating parameters screen display control mode on / off amount, bus, power communication and other analog signal control.

● control mode: local manual operation button control and remote automatic control of two can switch at any time.

● Status indication: valve open relay contact output to indicate off place and failure alarm signal output (optional 4 to 20mA), to reflect the valve opening and other instructions.

● Reliability Settings: hydraulic overload protection, motor overheat protection, limit protection, power outages, loss of signal.

The man-machine dialogue: Chinese display at a glance, the LCD display real-time display of the valve opening, parameter setting, the signal query set functions.

● fast action and self-locking: When the electrical, hydraulic actuator power failure or malfunction, requires valve to to reset quickly cut off or turn on the function of the function with self-locking to secure his position. Emergency fault occurs, the pump outlet water hammer phenomenon occurs will cause damage to the pumps, piping and external devices. The product in order to prevent water hammer phenomenon occurs, thus protecting the pump and an external device.

● Protection explosion-proof: control box, the hydraulic system has a strong anti-corrosion ability cabinet surface phosphating treatment, cylinder dynamic static mating surfaces have good sealing performance, IP65 protection class, explosion-proof EXdIIBT4 level.

Economic energy: the same output torque, the implementing agency power consumption is 1/3 of the energy of the electric, pneumatic 1/2 size, weight.

● Low noise: motor brushless motor directly driven by the two-way high-precision gear pump, distribution control into the hydraulic system, no mechanical conversion, high efficiency (up to 40 dB), low noise, long life, adjust the speed.

● free lid opening debugging: operating parameter settings, switch debugging is completed by a panel button, do not need to open the appliance cover, to prevent the dust in the environment such as moisture and harmful substances entering the motor and the electrical interior of the casing to improve the reliability.

2 key performance indicators and technical parameters

2.1.1 Performance indicators

● Input signal: 4 to 20mADC; 1VDC 5VDC; signal of the a 24VDC pulse and level; fieldbus signal.

● Output signal: valve position feedback signal 4 ~ 20mADC

Valve position status signal the passive dry contact contact capacity DC30V/5A AC250V/5A

State of alarm signal the passive dry contact contact capacity DC30V/5A AC250V/5A

● basic error: ± 1%

● Backlash: 0.5%

● deadband: 0.5%

● Fire control temperature: 79 ° C, 107 ° C, 163 ° C, 204 ° C ± 5 ° C

● Rated pressure of the hydraulic cylinder: 12MPa, 16MPa.

Power supply voltage: 220V, 380V AC. 50HZ

Ambient temperature: -30 ° C to +70 ° C

● hydraulic oil: Anti-wear hydraulic oil 46 #, 68 # (northern region: winter low temperature -25 ~ -45 ℃ hydraulic oil)

● Explosion levels: ExdIIBT4

● Protection class: IP67

|

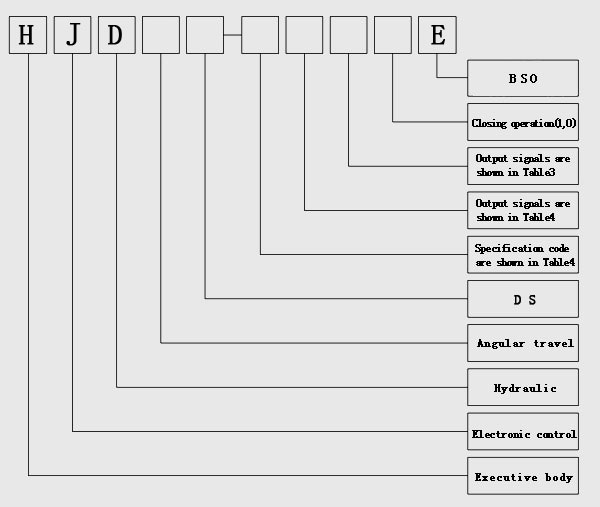

Specification code

|

KW

|

ml/r

|

N.M |

N.M |

s

|

Specification code

|

KW

|

ml/r

|

N.M |

N.M |

s

|

||

|

Hydraulic pressure

|

Spring

|

Hydraulic pressure

|

Spring

|

||||||||||

|

01

|

0.37

|

1

|

300

|

400

|

20

|

3

|

09

|

1.5

|

4

|

5000

|

7000

|

38

|

8

|

|

02

|

500

|

700

|

10

|

6000

|

9000

|

||||||||

|

03

|

600

|

1100

|

11

|

5

|

7500

|

11500

|

40

|

10

|

|||||

|

04

|

0.75

|

2

|

700

|

1200

|

25

|

4

|

12

|

9000

|

15000

|

||||

|

05

|

1200

|

2200

|

13

|

2.2

|

6

|

10000

|

20000

|

45

|

12

|

||||

|

06

|

1500

|

2500

|

35

|

6

|

14

|

15000

|

25000

|

||||||

|

07

|

1.1

|

3

|

3500

|

4500

|

15

|

3

|

8

|

20000

|

30000

|

50

|

14

|

||

|

08

|

4000

|

6000

|

|||||||||||

Note: 1. Running time for the standard table, if there are special requirements can be set according to user requirements;

4.1 input and output signal code shown in Table 3

|

Specifications

|

Input signal

|

Specifications格

|

Input signal

|

|

1

|

Amount of ON / OFF

|

1

|

Amount of ON / OFF

|

|

2

|

Analog4~20mA

|

2

|

Analog4~20mA 1~5V,1~10V

|

|

3

|

Digital

|

3

|

Digital

|

Example:

1.HJD-05221B

◆ electrical, hydraulic angle stroke single acting (spring return) implementing agencies: 0 ~ 70 º corner or of 0 ~~ 90 º the output torque 1200N.M, the input analog signal 4 ~ 20mA, output analog signal 4 ~ 20mA, with a hand to hold explosion-proof actuator.